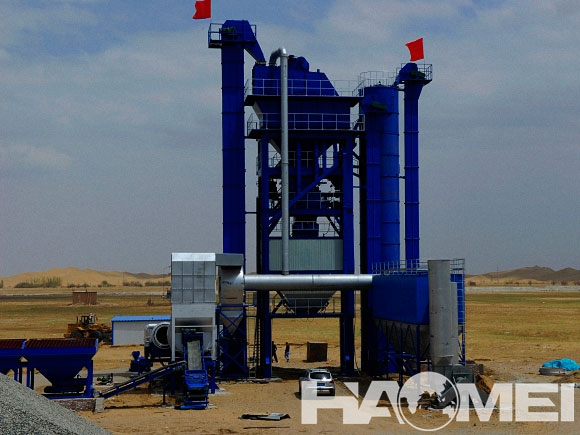

LB800 Asphalt Mixing Plant

-

Capability (standard conditions): 60t/h

-

The Mixer Rated Mix Capacity: 70Okg/batch

-

Oil Consumption(standard conditions): 5.5-7kg/t

-

Operation Mode: Automatism Control, Semi-automatism Control and Manual Control

- Description

- Parameter

- Drawing

- Inquiry

1. Cold aggregate supply system Components:Four aggregate hoppers and four belt feeders, Aggregate belt conveyer.

2. The tilted belt feeding conveyer Components: tilted belt feeding conveyer, Middle filter

3. Drying drum: Inside the drying drum fixing up diversified blades used for lifting aggregate, it should be easy to exchange heat between the flame and the aggregate, the drying drum is driven by gear, smoothly and evenly drive.

4.Light Oil burning system Components: A set of light oil burner; the light oil tank will be supplied by client, a set of oil pipes;

5.Hot aggregate elevator Characteristic:

Single rows of chains with double dowels, special structure for outlet to reduce the abrasion and noises.

6.Dust catcher system Components:Gravity dust catcher+cyclone dust catcher+ water dust catcher

7.Mixer tower assembly

(1)The vibrating screen with four layers. (single shaft outside).

(2)Hot material bins Components and specifications: Four separated bins with seal cover; overflowing device equipped will prevent exceeding aggregate blocking the screen mesh;

(3) Weighing bins1) aggregate weighing hopper: 2)Filler weighing hopper: 3) Asphalt weighing hopper:

(4) Mixer Characteristics:1). Mixers are made from European advanced techniques and equipped with synchronizing gear and pneumatic turning door; 2). Double shafts will contrarotate, which makes the aggregate turning up and down, and ensure the mixture mixed evenly.

(5) Asphalt spraying system Characteristic: It will spray asphalt quickly and evenly by pressure, good for shortening the mixing time and enhancing the output.

8.Filler supply system Components (1) Filler elevator: (2) filler temporarily storage silo

9. Pneumatic system Components:A set of air compressor, cylinder, electromagnetic valve and pneumatic pipeline;

10. Asphalt supply system Components: 0.1 million Kcal conduction oil stove, diesel oil burner, a dump tank(2 m3), a asphalt tank(30m3), pipes, valves and pump.

11.Electric control system (1) Control house (2) Electric control part

| Specification | Unit | Value |

|---|---|---|

|

Productivity (under standard conditions) |

t/h | 60 |

|

Oil Consumption (under standard conditions) |

kg/t |

5.5-7 |

| Mixer Rated Mix Capacity | kg/batch | 700 |

|

Operation Mode |

automatism control, Semi-automatism control and manual control |

|

|

Hot Mixture Discharge Temperature |

℃(common asphalt) | 130~160 |

|

Figure dimension |

m |

(length×width ×height): 36×18×13 |

|

Total installed power |

kw | 160.1 |

Related products

-

Drum Mobile Concrete Batching Plant

-

Dry Mix Concrete Batching Plant

-

Self Loading Concrete Mixer 1.2 Cubic

-

Self Loading Concrete Mixer 1.8 Cubic

-

Self Loading Concrete Mixer 2.6 Cubic

-

Self Loading Concrete Mixer 3.5 Cubic

-

Self Loading Concrete Mixer 4.0 Cubic

-

Self Loading Concrete Mixer 5.5 Cubic

-

Self Loading Concrete Mixer 6.5 Cubic

-

Concrete Mixer Pump

InquiryPlease feel free to submit your inquiry information to us. We will contact with you as soon as possible