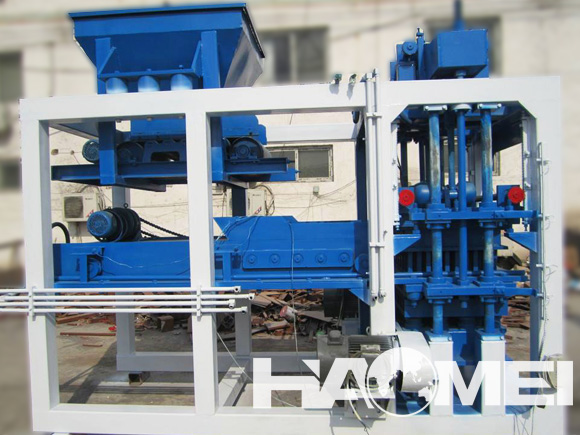

Concrete Block Making Machine

-

Model: QT series

-

Molding cycle: 15-20S

-

Capacity: 720-2160Pcs/Hr

-

Power: 20-48kw

- Product Details

- Specification

- Detailed service

- Inquiry

1. Specificaton of Haomei Concrete Block Machine

|

Brick/Block Size |

9" x 4" x3",10" x 5" x3",8" x 4" x4" |

|

Brick Raw Material |

Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

|

Usage/Application |

For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

|

No. Of Bricks Per Stroke |

4, 6, 8, 10,12, 14, 16 Pcs |

|

Pallets Size |

22" x 23" x 19mm (Thickness) |

|

Automation Grade |

Semi or Fully Automatic |

|

Brick/Block Type |

Solid, Interlock, Hollow, Paver |

|

Method |

Hydraulic Pressure |

|

System |

PLC Controlled |

|

Capacity(Blocks/Bricks ) |

1000-4000 pcs per hour |

|

Capacity per 8 Hours |

6000pcs to 40000 pcs |

|

Voltage |

440 Volt |

|

Space Required |

30 ft ( L) x 25 ft (W) x 16 Ft (H) |

|

Total Power Required |

22 HP to 50 HP |

|

Material |

Mild Steel |

|

Accessories |

Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

|

Treatment Time of Bricks/Blocks |

Minimum of 7- 8 Days |

2. Features of Haomei concrete block making machine

1) Mandatory synchronous vibrating system continuously provides high vibrating forces.2) Twin motor drives with variable frequency controller and vibrating controller ensure the products solid and perfect.

3) PLC control system and easy operation system touch screen parameters can be reset updated and amended to maximize the productivity automatic fault analyzing apparatus warning devices automatic interlock function are fitted out. Which prevent the production line from accident.

4) Quick material feeding system Multi-shaft 360 degree rotary and mandatory feeding which greatly improves the density and intensity of the blocks as well as reduces the feeding time to gain efficiency.

5) Heavy duty machine frame which using high-intensity steel and advanced heat treatment guarantee the structure endurable.

|

Brick/Block Size |

9" x 4" x3",10" x 5" x3",8" x 4" x4" |

|

Brick Raw Material |

Cement, Fly Ash, Sand, Stone Dust, Gysum, Lime Sludge,etc |

|

Usage/Application |

For Making,Fly ash bricks,Concrete Blocks,Paver Blocks,Solid Blocks, Cement Blocks, Hollow Blocks |

|

No. Of Bricks Per Stroke |

4, 6, 8, 10,12, 14, 16 Pcs |

|

Pallets Size |

22" x 23" x 19mm (Thickness) |

|

Automation Grade |

Semi or Fully Automatic |

|

Brick/Block Type |

Solid, Interlock, Hollow, Paver |

|

Method |

Hydraulic Pressure |

|

System |

PLC Controlled |

|

Capacity(Blocks/Bricks ) |

1000-4000 pcs per hour |

|

Capacity per 8 Hours |

6000pcs to 40000 pcs |

|

Voltage |

440 Volt |

|

Space Required |

30 ft ( L) x 25 ft (W) x 16 Ft (H) |

|

Total Power Required |

22 HP to 50 HP |

|

Material |

Mild Steel |

|

Accessories |

Main Press Machine with Vibrator System, Rollers Pan Mixture, Belt Conveyor, Bearing Conveyor, Electronic Control Panel, Hydraulic Power Pack, Material Trolley, Hydraulic Pallets trolley. |

|

Treatment Time of Bricks/Blocks |

Minimum of 7- 8 Days |

If you have little experience in building brick making factory. We can help them to do market research and assist them to choose the most proper machine.

2. Provide related drawing of program.

Haomei are professional and have rich experience in manufacturing hollow block making machines, so we have clients all over the world. So we have many cases for your reference if you do not know how to begin your blocks business.

3. On site installation, debugging, free training and maintenance.

We provide engineer to your local place, help you install the machine, demonstrate the operation, and training your workers. Continuous guidance during installation.

4. Timely help when needed.

Commonly, we will provide considerate service for free(excluding the commuting expenses). As long as the clients need help, we will give timely technology support by phone or video. If it is necessary, our engineers will fly to the local construction site and solve problems for the clients.

Related products

-

Drum Mobile Concrete Batching Plant

-

Dry Mix Concrete Batching Plant

-

Self Loading Concrete Mixer 1.2 Cubic

-

Self Loading Concrete Mixer 1.8 Cubic

-

Self Loading Concrete Mixer 2.6 Cubic

-

Self Loading Concrete Mixer 3.5 Cubic

-

Self Loading Concrete Mixer 4.0 Cubic

-

Self Loading Concrete Mixer 5.5 Cubic

-

Self Loading Concrete Mixer 6.5 Cubic

-

Concrete Mixer Pump

InquiryPlease feel free to submit your inquiry information to us. We will contact with you as soon as possible