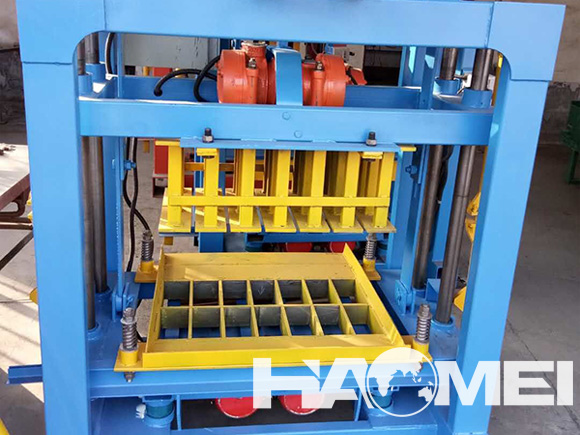

QT4-15 Fly Ash Brick Machine

-

Model: QT4-15

-

Molding cycle: 15-20S

-

Capacity: 720Pcs/Hr

-

Power: 20kw

- Product Details

- Specification

- Detailed service

- Inquiry

1. Technical Specifications

|

Molding cycle |

15-20s |

|

Production capacity |

5760~37440pcs/shift(8h) |

|

Vibration frequency |

4800-5100r/min |

|

Exciting power |

20MPA |

|

Overall power |

67KW |

|

Overall dimension |

5420*1550*2940mm |

|

Molding form |

Vibration and Pressure |

|

Pallets size |

580x570x30mm |

2. Capacity

|

Item |

Size(mm) |

Qty/mold |

Cycle molding |

Per day |

|

Hollow Block |

400×200×200 |

10pcs |

15~20s |

13000-15000pcs |

|

Solid block |

240x115x53 |

52pcs |

15~20s |

42000-44000pcs |

|

Paver brick |

200×160×60 |

22pcs |

15~20s |

25000-28000pcs |

|

interlocking bricks |

200x160x60 |

22pcs |

15~20s |

25000-28000pcs |

3. Features of Haomei Fly ash bricks machine

- Excellent production rate

- Corrosion resistant finish

- Sturdy construction

- Easy operations

- Longer functional life

- Reliable performance

|

Molding cycle |

15-20s |

|

Production capacity |

5760~37440pcs/shift(8h) |

|

Vibration frequency |

4800-5100r/min |

|

Exciting power |

20MPA |

|

Overall power |

67KW |

|

Overall dimension |

5420*1550*2940mm |

|

Molding form |

Vibration and Pressure |

|

Pallets size |

580x570x30mm |

If you have little experience in building brick making factory. We can help them to do market research and assist them to choose the most proper machine.

2. Provide related drawing of program.

Haomei are professional and have rich experience in manufacturing block making machines, so we have clients all over the world. So we have many cases for your reference if you do not know how to begin your blocks business.

3. On site installation, debugging, free training and maintenance.

We provide engineer to your local place, help you install the machine, demonstrate the operation, and training your workers. Continuous guidance during installation.

4.Timely help when needed.

Commonly, we will provide considerate service for free(excluding the commuting expenses). As long as the clients need help, we will give timely technology support by phone or video. If it is necessary, our engineers will fly to the local construction site and solve problems for the clients.

Related products

-

Drum Mobile Concrete Batching Plant

-

Dry Mix Concrete Batching Plant

-

Self Loading Concrete Mixer 1.2 Cubic

-

Self Loading Concrete Mixer 1.8 Cubic

-

Self Loading Concrete Mixer 2.6 Cubic

-

Self Loading Concrete Mixer 3.5 Cubic

-

Self Loading Concrete Mixer 4.0 Cubic

-

Self Loading Concrete Mixer 5.5 Cubic

-

Self Loading Concrete Mixer 6.5 Cubic

-

Concrete Mixer Pump

InquiryPlease feel free to submit your inquiry information to us. We will contact with you as soon as possible